WD-120 Double Stage

Plastic Recycling Machine

Main parts

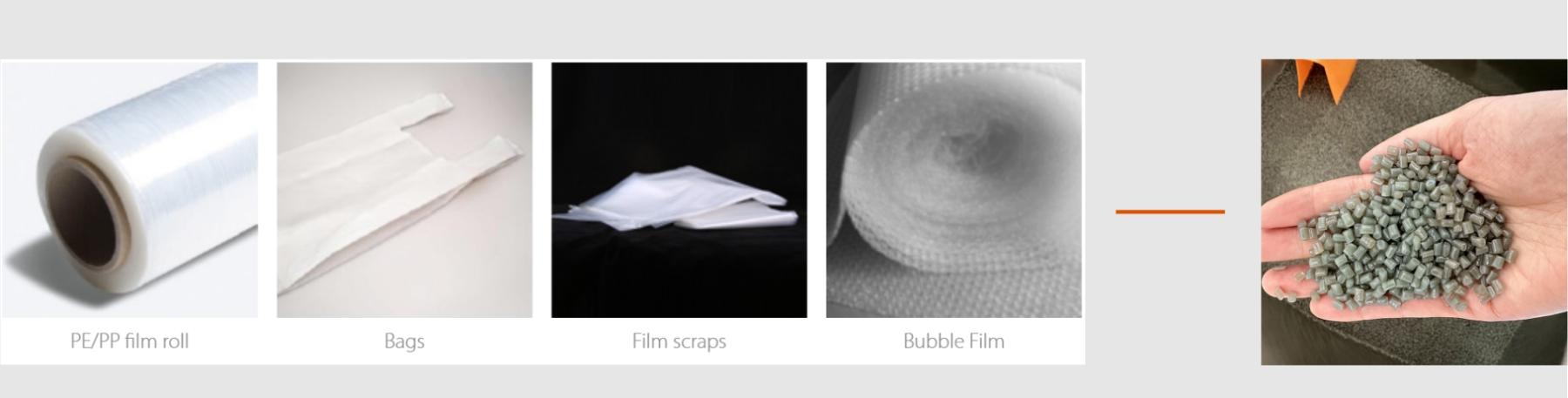

This plastic recycling machine suit for Printed and nonprinted PE, PP film, multi-layered film, shrink film, stretch film, PE and air bubble film.

Mobile / Whatsapp:

Email Us

| Model | Screw diameter | Screw aspect ratio | Motor Power | Capacity |

| WD-100/100 | 100mm/100mm | 10-25:1 | 22KW/15KW | 80-100kg/h |

| WD-120/120 | 120mm/120mm | 10-25:1 | 37KW/15KW | 150-200kg/h |

| WD-140/120 | 140mm/120mm | 10-25:1 | 55KW/15KW | 250-300kg/h |

| WD-160/140 | 160mm/140mm | 10-25:1 | 75KW/22KW | 350-400kg/h |

| WD-180/140 | 180mm/160mm | 10-25:1 | 90KW/30KW | 450-500kg/h |

Introduction To WD-120 Double Stage Plastic Recycling Machine:

The Plastic Recycling Granulating Machine is specialized equipment designed for recycling and granulating plastic films and bags. It is equipped with a compacting machine that pre-compacts the film into smaller granules, facilitating easy feeding into the screw barrel of the extruder. This enhances efficiency and boosts production capacity significantly. Moreover, it features a vacuum exhausting system on the extruder barrel, effectively removing moisture from the material. This results in impeccable final granule quality.

Additionally, the machine is outfitted with a double-station, high-speed hydraulic non-stop screen changer. This efficient component filters out impurities from the plastic melt, ensuring the purity and quality of the final product. Furthermore, the pelletizing process employs water cooling, which simplifies operation and yields granules with a desirable shape and appearance.

Overall, the Plastic Recycling Granulating Machine represents a sophisticated solution for plastic recycling, offering high efficiency, superior granule quality, and ease of operation.

Machine configuration:

Conserves Natural Resources

Recycling is important in conserving natural resources in the plastic manufacturing industry. Producing new plastic products from virgin materials requires the extraction and refining of crude oil or natural gas, both of which are non-renewable resources.

Reduces Waste

Recycling plays a critical role in reducing waste in the plastic manufacturing industry. Plastic waste is a significant environmental problem, with millions of tons of plastic ending up in landfills and oceans yearly.

Saves Energy

Recycling plays an important role in saving energy in the plastic manufacturing industry. Producing new plastic products from virgin materials requires a significant amount of energy, including the energy required to extract and refine crude oil or natural gas, transport materials, and produce plastic products.

Cost-Effective

Recycling is a cost-effective solution in the plastic manufacturing industry. The cost of producing new plastic products from virgin materials can be high due to the energy, raw materials, and transportation required.