HOME

HOME

ALL MACHINERY

ALL MACHINERY

Air bubble bag making machine series

Air bubble bag making machine series

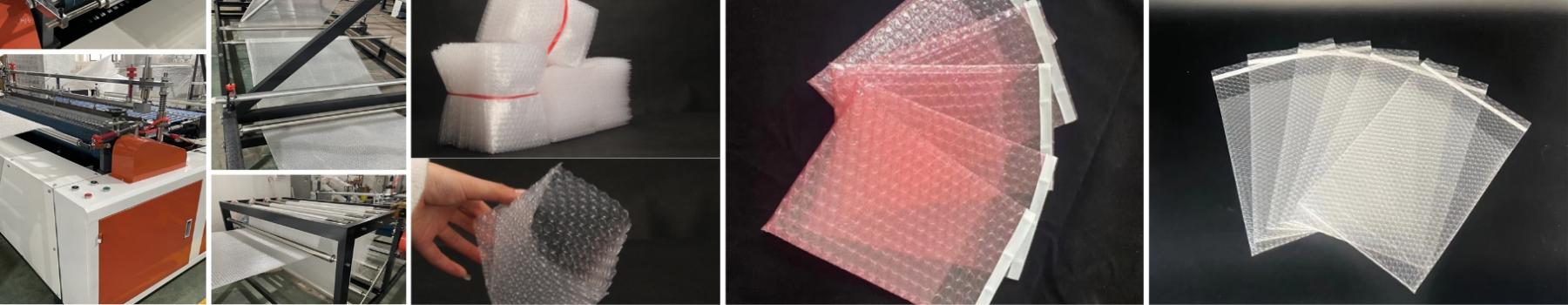

2 side sealing ordinary bubble bag making machine

2 side sealing ordinary bubble bag making machine

2 side sealing ordinary

bubble bag making machine

Main parts

Air bubble bag making machine 2 side sealing is specialized in making 2 layer and 3 layer air bubble bags.

Mobile / Whatsapp:

Email Us

| Model | WD-800 | WD-1000 | WD-1200 |

| Max width(mm) | 10-750 | 10-950 | 10-1150 |

| Max length(mm) | 50-2000 | 50-2000 | 50-2000 |

| Capacity(pcs/min) | 20-200 | 20-200 | 20-200 |

| Power(KW) | 3.2 | 4 | 6 |

| Weight(KG) | 1500 | 1800 | 2400 |

| Dimension(m) | 4.4x2.8x1.8 | 4.5x3x2 | 4.6x3.2x2 |

Introduction 2 side sealing ordinary bubble bag making machine:

The bubble bag making machine 2 side sealing is specially designed for PE-coated EPE foam or without PE-coated

EPE foam. It can also be used for air bubble film material. It is widely used for packaging electrical products, toys, touch

screens, etc. It features a fully PLC-controlled system with an automatic counter and alarm system, ensuring excellent

sealing quality.

This machine integrates the best inherent advantages, with a reasonable mechanical structure, low operating noise,

microcomputer control, PLC touch screen display, and bilingual (Chinese and English) operation instructions. It is ideal

for producing bubble bags and EPE foam bags.

Machine configuration:

1) Uses a PLC computer control system with a man-machine interface for simple operation and accurate bag length.

2) Double-sided water-cooling for rapid cooling and neat, firm sealing.

3) Automatic folding and feeding, allowing for the creation of bags with straight edges, eliminating misplacement failures, and reducing labor costs.

4) Capable of feeding multiple bags simultaneously, doubling efficiency.

5) The cutting mechanism is designed to handle thinner and softer bubble film and pearl cotton bags without material blocking failures.

6) Adjustable heat sealing time parameters, suitable for making pearl cotton bags with a thickness of less than 2mm without additional mechanisms.

7) Produces firm sealing lines and offers high production efficiency.